Pump Monitoring

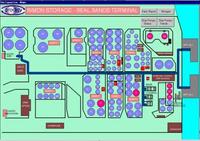

PC based pump monitoring at a petroleum products tank farm, replacing obsolete control panel equipment.

PC based pump monitoring at a petroleum products tank farm, replacing obsolete control panel equipment. The system was designed as a replacement for an ageing control panel housing old ammeters and chart recorders which were used for monitoring numerous pumps around the site.

As the petroleum products are transferred between ships and the various tanks, or between tanks, the current drawn by each individual pump is monitored.

Key Benefits |

|

| Pump Monitoring |

|

|

|

|

All signals in the system are recorded to hard disk which enables a full trend history of pump usage, going back several years, to be viewed by the operator. This pump history means that the scheduled preventative maintenance periods can be reviewed and the data analysed to determine if faults can be detected earlier.

The currents drawn by the pumps are also monitored against a set of pre-defined alarm levels and in the event of a fault with a pump, a flashing annunciator is triggered to warn the maintenance staff.

The monitoring system is fully configurable by the customer so that as their requirements change, they can expand the system to cover, for example, the tank levels.

If you have an application and would like more information please contact us.